How it works - Science Led Cleaning

Rozone has worked with the science of bioremediation for nearly 30 years – nature's clever way of cleaning up, and we still believe it’s the best solution for the parts cleaning market.

The system comprises of three distinct parts: the ROwasher parts cleaning machine, our ROwash Degreasing Solution and Microbial Filter Mat. The filter mat releases millions of micro-organisms into the system where they break down or “eat” oil and grease that's washed off dirty parts into the ROwasher, turning it all into harmless carbon dioxide and water. This process leaves the fluid clean and strong for every use, reducing the need for hazardous waste disposal and the associated costly service contract.

We strongly believe that the best way of introducing these “oil-eating” microbes into the parts washer system and keeping them working at their optimum level in the degreasing solution is via a filter mat. To verify this, we have been working hand-in-hand with the microbiology team at the University of Wolverhampton and our own formulation scientists to ensure that we provide market-leading degreasing fluid and microbial filter mats that provide the greatest innovation in parts cleaning. Existing Rozone customers can be assured that our developments are only bringing improvements to their current parts washer systems.

Microbial Filter Mat

The ROwasher Microbial Filter Mat serves 3 purposes:-

- To deliver over 200 million friendly oil eating microbes into the parts washer system

- Provide the ideal environment for the microbes to breed and colonise

- Filter out large contaminants to prolong the “life” of the fluid

Our Microbiologists have identified and supplied specific microbes in our Filter Mat to degrade the different types of oil and grease found in the Industries we work. All are Bio-Safety Level 1 Microbes and are non-pathogenic or no risk to humans or animals.

ROwash Degreasing Solution

Whilst the microbes keep the fluid clean, to clean the dirty parts our scientists have formulated ROwash - a degreasing solution that works hand-in-hand with our Microbial Filter Mat. As powerful as solvent but without the hazards, ROwash is designed to degrease oily components quickly and effectively. Solvent-free & pH neutral it is the ideal solution for the microbes to subsist in. Heated by the machine up to 42°c, which helps to reduce the viscosity of oil and grease on parts, making removal easier, this surfactant degreaser is more pleasant to use and releases no vapours or VOCs. The concentration of surfactant in the formula has been specially chosen by our Chemists to make the contaminant particles (hydrocarbons) the smallest they can be, so the microbes can easily break them down. This ensures the fluid stays cleaner for longer.

ROwasher`s Easy Installation

Rowasher Microbial Filter Mat

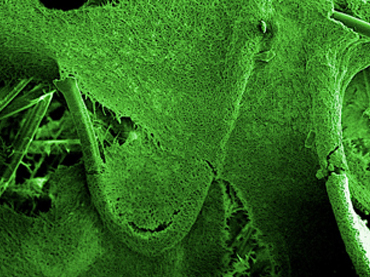

We have scientifically proven that the filter mat is the best way of delivering the microbes into the ROwasher system as it then acts as scaffolding, helping to create a breeding ground for the microbes which cling, grow and breed on the fibres to form a reservoir of oil eating microbes.

This bio film of microbes means that, for the month-long life of the filter, there is a constant supply of microbes working to degrade the hydrocarbons and maintain the optimum cleaning performance of the parts washer.

ROwasher Microbial Filter Mat under microscope

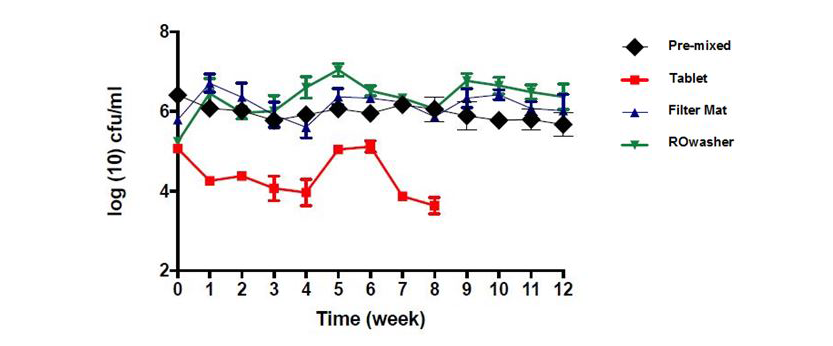

Figure 1. Viable count of microbes in ROwasher over 12 weeks compared with competitor bioremediating parts washers.

Figure 2. Oil degradation rate in the ROwasher over 12 weeks compared with competitor bioremediating partswashers. The key denotes the different microbe delivery methods and their total oil degradation result at week 12.

* Results only recorded to 8 weeks due to machine failure.

Eco Mode

With our machine innovation, we are now introducing the energy saving Eco Mode to the ROwasher, where the temperature drops to 37°c when not in use (overnight and weekends). This not only saves on energy costs but we have now developed the ideal environment for the microbes to grow; an operating temperature of 42°c is great for cleaning but we have introduced microbes which thrive at lower temperatures too meaning healthy microbes that will best degrade the oil ensuring our customers achieve the best possible cleaning performance. We balance cleaning performance with bioremediation to achieve the best results.

Easy Maintenance

Thanks to the ROwasher`s unique bioremediating technology, waste fluid generation is dramatically reduced, cutting the expense of hazardous waste removal on a regular basis by a service contractor - bringing significant savings to the user.

The ROwasher is safe and easy to maintain in-house with only a monthly change of the Microbial Filter Mat to replenish the microbe colony and a top-up of ROwash Solution when the low fluid indicator light shows.

ROwasher not what you need? Take a look at our range of hotwashers

Automatic, aqueous cleaning machines. The aqueous parts washer cleans and dries parts providing an entirely automatic, cost effective and safe cleaning process.